The terms poka-yoke, mistake-proofing and error-proofing make quite a few problems due to the fact that there is no clear, no uniform definition of these terms (one can even find many studies using these phrases interchangeably). And while this is not a problem for many companies, for whom the most important thing is that these solutions, regardless of the name, work effectively, in the automotive industry, for example, the situation is not so simple. This is because its current IATF 16949 standard for error-proofing solutions has specific requirements (e.g., the obligation to include in the control plan and develop response plans in case of their failure) that are not there for, for example, mistake-proofing.

POKA-YOKE doesn’t offer a guarantee!

It is wrong to say that a poka-yoke solution is the only one that makes it impossible to make a mistake. Just go back to the early days of poka-yoke and its creator Shigeo Shingo – the first was to give an operator at the same time (in pairs) elements to reduce the possibility that he would forget one. Clearly, such a solution didn’t guarantee a flawless process, but only strongly reduced the possibility of error. The concept of poka-yoke should therefore be understood as a set of solutions designed to reduce the risk of supplying products not according to specification to the customer.

MISTAKE-PROOFING VS ERROR-PROOFING

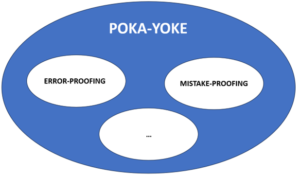

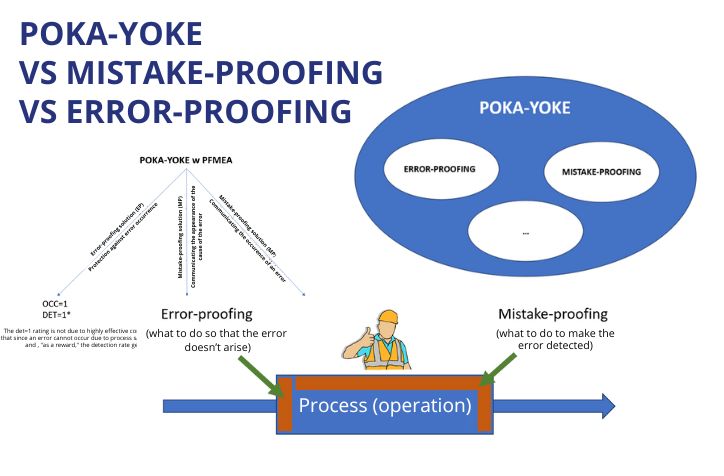

It can be said that mistake-proofing and error-proofing solutions have a lot in common, but first and foremost is that both are poka-yoke solutions.

Pic. 1. POKA-YOKE types Source: own study

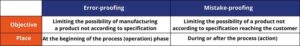

To distinguish between them, it is easiest to pay attention to two aspects: objective and the place of application.

Table 1: Comparison of error-proofing and mistake-proofing

Source: own study

Pic. 2 The place of POKA-YOKE types in the process Source: own study

Very importantly – the above division should be treated as conventional, because, as written in the introduction, by some, these terms are used interchangeably, and this should not be considered an error. However in the automotive context, the situation is somewhat different due to the fact that the IATF 16949 standard includes an official definition of error-proofing stating that it is a solution arising from the design of a product or process to prevent the production of product not according to specification.

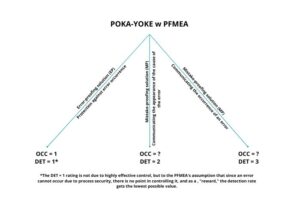

POKA-YOKE solutions in PFMEA

PFMEA analysis is based on determining two risk factors – the occurrence of failure cause (OCC) and the detection (DET). This is directly related to error-proofing (hereafter EP) and mistake-proofing (hereafter MP) solutions. The OCC and DET indicators are determined on a scale of 1-10, where “1” represents an ideal situation and “10” a very bad situation (i.e., very frequent occurrence or no detection). It is therefore possible to directly relate EP and MP to OCC and DET in a PFMEA analysis-shown schematically in the figure below.

Pic. 3 POKA-YOKE in PFMEA Source: own study

Thus, it can be seen that EP impinges on both OCC and DET, while MP is a solution that only affects DET detectability.

Summary

It is worth making it clear again that the terms poka-yoke, error-proofing and mistake-proofing are used very often interchangeably, and there is nothing wrong with that. As long as this interchangeability doesn’t lead to errors in documentation as in the automotive industry, it is enough to focus on the effectiveness of their operation (inspections, testing, specific MSAs). The important thing, after all, is the quality of the products, not academic quibbles about what’s called what – although this is, of course, a truism.

Leave A Comment

You must be logged in to post a comment.