Have you ever wondered how many types of FMEA analysis there are?

We have! And that’s why we decided to prepare this material for you.

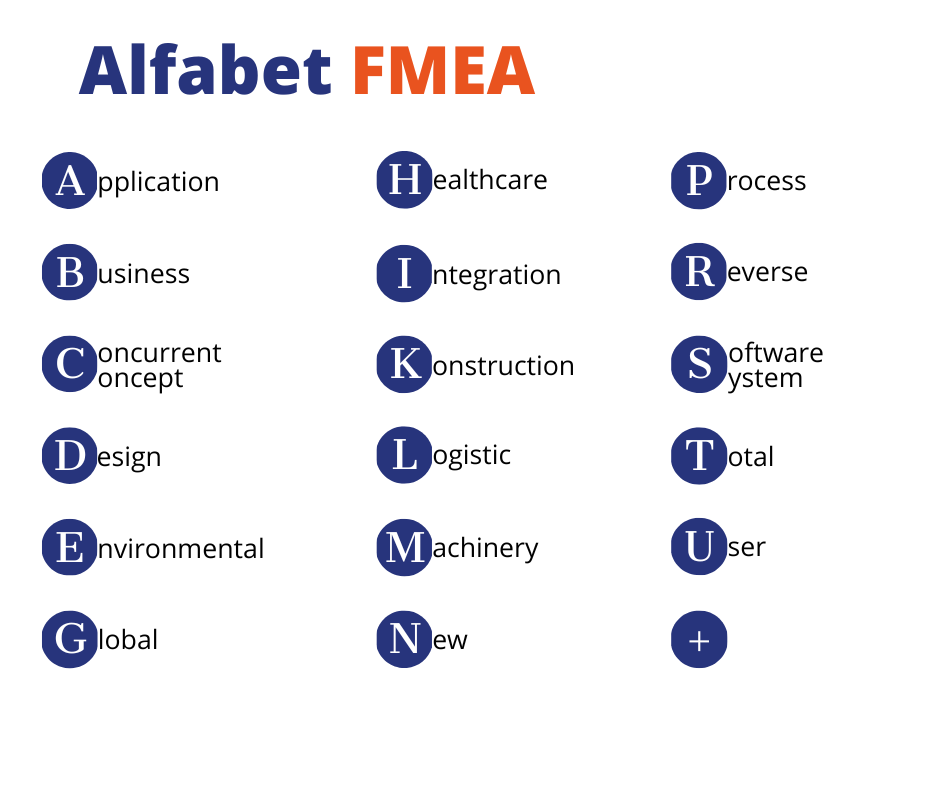

Here is a collection of different types of FMEA analysis:

A – Application FMEA

An analysis used to assess whether products and machinery that are purchased from third-party suppliers are likely to fail due to improper use.

B – Business FMEA

Analysis of the types and effects of errors in business processes (identification of weak points in the desired outcome of the business process).

C – Concurrent FMEA

Analysis of the types and effects of concurrent failures of a component-based software system.

C – Concept FMEA

It is used to accurately analyze system and subsystem concepts at the early stages of design.

D – Design FMEA (FMEA of the product)

Analyse the failure effects and causes of errors made at the product design stage.

E – Environmental FMEA

Analysis of the organization and its processes through the prism of environmental requirements and aspects, with the aim of reducing the negative impact of the organization on the environment.

G – Global FMEA

An analysis type designed to streamline globally distributed projects. Used to improve globally distributed projects. GFMEA assesses the potential types and effects of global distribution failures.

H – Healthcare FMEA

Analyze the causes and consequences of noncompliance in health care.

I – Integration FMEA

Analysis for identifying risks of complex products that integrate several subsystems. This most often applies to mechatronic products.

K – Konstruction FMEA = DFMEA

L – Logistic FMEA

A type of analysis for logistics processes in terms of possible nonconformities and their consequences.

M – Machinery FMEA

Analysis of possible nonconformities and their effects on machine operation. MFMEA is one of the best sources of information for planning fleet maintenance (TPM) activities.

N – New FMEA

A new approach to FMEA analysis aimed at selecting the best supplier from the environment in the supply chain.

P – Process FMEA

Analysis of the types and consequences of errors made during the process.

R – Reverse PFMEA

Reverse analysis to re-evaluate the reliability of AP or RPN values determined by the PFMEA and confirm the compliance of defined defects, causes, prevention and control.

S – System/Software FMEA

Analysis of the types and effects of defects in software.

T – Total FMEA

A technique called total analysis of the types and effects of defects which bridges the gaps created by traditional FMEA analysis.

U – Use FMEA

An analysis that refers not only to defects relating directly to the product (for which the designer or the manufacturing process is responsible), but also to errors relating to what the user will do with the product.

FMEA-MSR (FMEA for Monitoring and System Response)

Analysis for monitoring and response of systems. Its purpose is to identify how systems are likely to fail when used by the end customer. This type of analysis complements DFMEA.

Regardless of what type of analysis you are doing, we will be happy to answer your questions and help address your concerns about a particular type of FMEA analysis.

Feel free to contact us visit our forum! Questions can also be added in the comments below the post!

Leave A Comment

You must be logged in to post a comment.