D

More information is available regarding the expected FMEA manual published jointly by AIAG and VDA!

During the webinar organized by AIAG, the publication date of the manual was confirmed. It will be published in two languages – English and German in June. It is still required to be approved by the VDA QMA (scheduled for early May).

The new FMEA is presented on the one hand as a risk analysis and management tool, but also as a method to help reduce quality costs. Too low reduction of quality costs will be considered as insufficient FMEA effectiveness.

In order to improve the risk analysis, a number of significant substantive changes have been introduced.

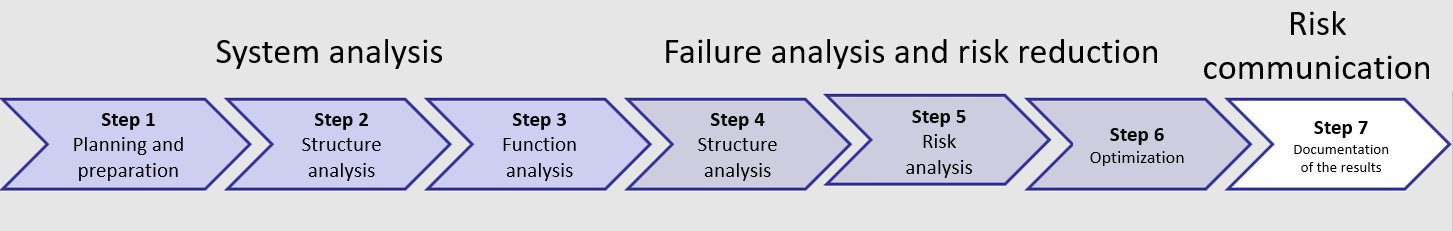

The 6-point analysis process presented in the draft was supplemented with step 7 related to risk communication.

The changes include the modification of the S, O, D tables. On the one hand, the approach to impact assessment used by experienced moderators has been formalized, taking into account not only the effects at the client but also, inter alia, internal effects, and on the other hand, the approach to assessing the incidence rate was completely changed, replaced by the assessment of the effectiveness of prevention.

An important change is the introduction of Action Priority, which is to replace the current RPN. The AP value will be defined as High, Medium, and Low, based on the tables showing the importance of the component. In the new solution proposed by AIAG and VDA, SEV will be the most important, followed by OCC and finally DET. This change is intended to emphasize differences in the severity of errors, such as between errors with high significance and low frequency of occurrence from those with low significance and high frequency of occurrence.

A new type of FMEA will also appear in the new manual – FMEA MSR, which we have already written about here.

Another formalized thing that results from best practice is to look for the causes of non-compliance in several categories: man, machine, environment and material.

Finally, one of the most important information for the teams creating FMEA – you will not need to correct the FMEA analyzes already carried out!

Leave A Comment

You must be logged in to post a comment.